The Waste Management Company of Pen Argyl was a recently established waste management company funded by the Federal government. This facility will create 126 additional jobs and assist the community in many other ways. One of these ways is through a Federal Matching Grant. This type of grant helps local governments and businesses develop their communities by attracting new businesses and jobs.

126 jobs

Pen Argyl has 126 jobs created by the expansion of a waste management facility. The proposed landfill will provide an estimated $4 million in annual benefits to the town. It will also support many local businesses and initiatives. There is also the possibility of overtime, which could bring a person's salary up to six figures.

The expansion is part of a larger plan to reduce landfill costs, which includes reducing emissions and creating new jobs. Plainfield has a company that provides free trash pickup, recycling and habitat for wildlife. The company is required to pay a $2.2million community host fee. This amount amounts to $1.042 per household. This host fee will decrease to zero if the landfill is closed.

Federally funded

The Federally funded waste Management Program in Pen Argyl is Pennsylvania's oldest, dating back to the 1930s. It has been a successful venture that helps local governments manage waste, while at the same time creating jobs for local residents. President Clinton launched the program and it continues to be run today. A small portion of the grant from the program supports the salaries of two borough police officers.

The landfill has been a major source of revenue for the local community, with a tax rate of 1 mill a year. This is roughly $50 per year for an average homeowner. Green Knight, an environmentally friendly energy company, provides $250,000 per year to the town. It burns landfill methane. Waste Management also provides $150,000 to the township. Waste Management recently demolished a five-story Bet building.

Northampton County

Northampton County has increased its solid waste and recycling capabilities. The county operates manned recycling centers for glass, paper, and aluminum. It also accepts food and beverage cartons and waste oil. Special Olympics Virginia has partnered with the county to offer clothing collection bins at local waste collection centres.

Northampton County waste management officials need your feedback on a proposal to expand the Grand Central Sanitary Landfill. The owners of the landfill want to double the landfill's size. Residents are invited to attend an informational meeting. The company would like to expand the solid trash zoning district by an additional 211 acres. Currently, the landfill has a permitted daily volume of 2,750 tons. The landfill has plans to expand, which could bring that number up to 5,000 tons daily. The expansion will create additional land for support activities as well as a buffer zone around the landfill.

Matching grant

The Department of Conservation and Natural Resources awarded $19,500 to the Borough of Pen Argyl for a master plan. This grant will fund materials and installation of new equipment. It must be equaled by a $19,000.500 contribution from the community. The Borough is very grateful to Pen Argyl Senior Women's Club Pen Argyl Senior Citizens Club, Waste Management, Pen Argyl Area Concerned Citizens and Park Pals.

FAQ

What kind of people use Six Sigma?

Six Sigma is well-known to those who have worked in operations research and statistics. However, anyone involved in any aspect of business can benefit from using it.

This requires a lot of dedication, so only people with great leadership skills can make the effort to implement it.

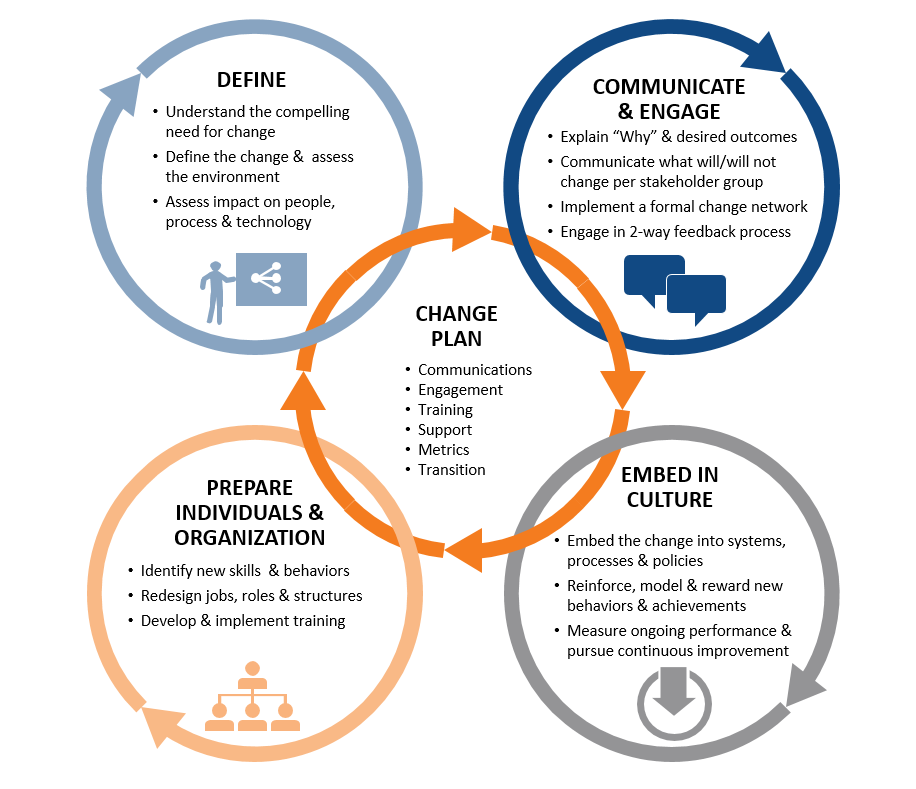

What are management concepts?

Management concepts are the fundamental principles and practices that managers use when managing people and their resources. These include topics such as human resource policies and job descriptions, performance assessments, training programs and employee motivation.

What are the 4 major functions of management

Management is responsible for organizing, managing, directing and controlling people, resources, and other activities. It includes the development of policies and procedures as well as setting goals.

Management helps an organization achieve its objectives by providing direction, coordination, control, leadership, motivation, supervision, training, and evaluation.

Management has four primary functions:

Planning - Planning involves determining what needs to be done.

Organizing – Organizing means deciding how to organize things.

Directing - Directing means getting people to follow instructions.

Controlling: Controlling refers to making sure that people do what they are supposed to.

What is the difference of a program and project?

A program is permanent, whereas a project is temporary.

A project has usually a specified goal and a time limit.

It is often done in a team that reports to another.

A program typically has a set goal and objective.

It is often implemented by one person.

What are some of the common mistakes made by managers?

Managers can make their jobs more difficult than necessary.

They may not delegate enough responsibilities to staff and fail to give them adequate support.

Additionally, many managers lack communication skills that are necessary to motivate and direct their teams.

Managers set unrealistic expectations and make it difficult for their team.

Some managers may try to solve every problem themselves instead of delegating responsibility to others.

What are the steps of the management decision-making process?

The decision-making process for managers is complex and multifaceted. It involves many factors, including but not limited to analysis, strategy, planning, implementation, measurement, evaluation, feedback, etc.

Management of people requires that you remember that they are just as human as you are, and can make mistakes. As such, there are always opportunities for improvement, especially when you put in the effort to improve yourself.

We explain in this video how the Management decision-making process works. We discuss different types of decisions as well as why they are important and how managers can navigate them. The following topics will be covered:

Statistics

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

External Links

How To

How does Lean Manufacturing work?

Lean Manufacturing is a method to reduce waste and increase efficiency using structured methods. These processes were created by Toyota Motor Corporation, Japan in the 1980s. The goal was to produce quality products at lower cost. Lean manufacturing eliminates unnecessary steps and activities from a production process. It is composed of five fundamental elements: continuous improvement; pull systems, continuous improvements, just-in–time, kaizen, continuous change, and 5S. Pull systems involve producing only what the customer wants without any extra work. Continuous improvement is constantly improving upon existing processes. Just-intime refers the time components and materials arrive at the exact place where they are needed. Kaizen means continuous improvement. Kaizen involves making small changes and improving continuously. Five-S stands for sort. It is also the acronym for shine, standardize (standardize), and sustain. These five elements work together to produce the best results.

Lean Production System

The lean production system is based on six key concepts:

-

Flow - The focus is on moving information and material as close as possible to customers.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S's - Sort, Set In Order, Shine, Standardize, and Sustain;

-

Kanban: Use visual signals such stickers, colored tape, or any other visual cues, to keep track your inventory.

-

Theory of Constraints - Identify bottlenecks in the process, and eliminate them using lean tools such kanban boards.

-

Just-in-time - deliver components and materials directly to the point of use;

-

Continuous improvement - Make incremental improvements rather than overhauling the entire process.