Management of change (MOC), is a concept that many people don't know about. This best practice is a great way to avoid unintended consequences and keep your organization running smoothly. More information about MOC (and its stages) can be found below. These are the eight most important MOC stages. These stages will help you manage organizational change with ease. So, what is MOC? Why is this important?

MOC is a process

MOC is often ignored by many organizations. Uncertainty and lack of process safety information are two common causes of workplace accidents. Organizations often rush through the change to get it over with, ignoring the need for a thorough management of risk. Accidents could occur when organizations are not redesigning existing production processes. This is especially true for industries dealing with energy and hazardous substances.

It consists of eight stages

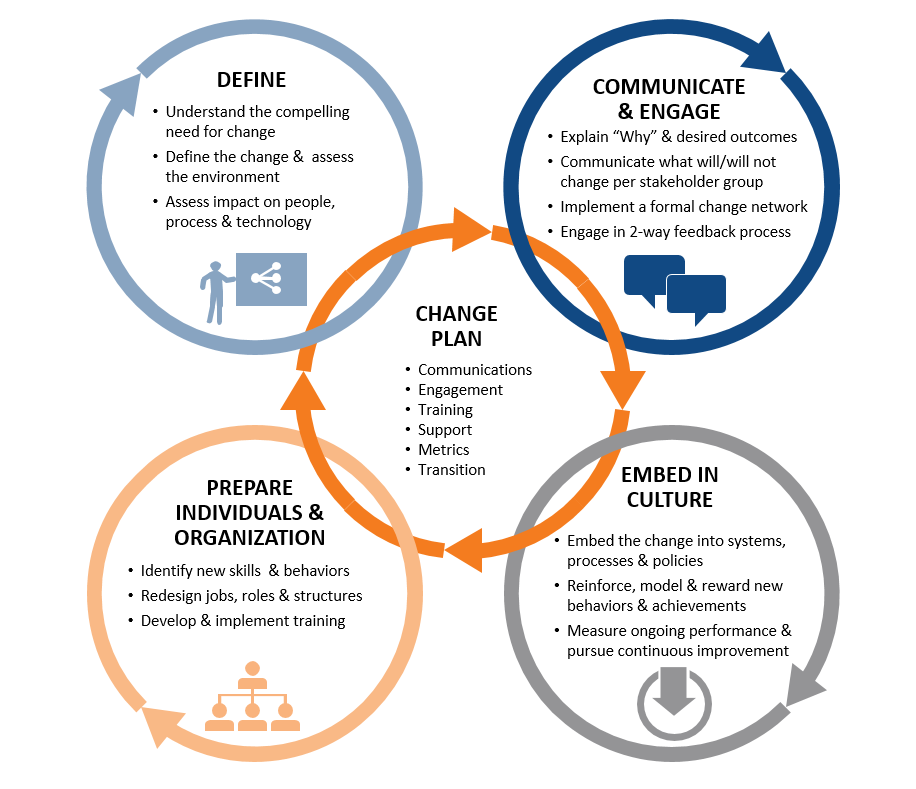

The McKinsey Change Management Model defines the change process as an architectural process with eight stages: preparation, implementation, monitoring, evaluation, and sustainment. The first three stages are focused on the business aspect of change. The second two focus on the emotional aspects. The eighth stage must consider culture. In order to embrace new practices within the existing work culture, it is necessary to consider culture. Successful change management requires that the organization's culture can adapt to these changes.

It helps avoid unintended consequences

Unintended consequences occur because people don't always think through their actions before making a decision. For example, people may make decisions based on past performance rather than analyzing the current situation. This can result in decisions that have unintended consequences and can ultimately be counterproductive. There are ways to manage changes and minimize undesirable consequences. One example is implementing a new process that may have positive or negative unintended consequences. For example, if a new technology is introduced, a test group will be established to assess its impact.

It is best practice

It is possible to make a difference in the future by managing change effectively. This best practice can lead to organizational transformations by identifying the vision and engaging the team. There are also soft aspects to change management, so be aware of these. These elements are crucial to any change management project's success. These elements should be considered in order to make the entire change process as smooth as possible.

It is vital to maintain regulatory compliance

Companies must track metrics and report on how they are performing to ensure compliance with regulatory requirements. These metrics can help to evaluate process adherence and identify risks/performance indicator. In addition, metrics can help identify regulatory changes and the impact they will have on an organization. Monitoring change can help proactive organizations anticipate future regulatory requirements and show evidence of compliance. We will be discussing some of the most important metrics that need to be tracked and reported in this article.

FAQ

What is the difference between Six Sigma Six Sigma and TQM?

The main difference between these two quality-management tools is that six-sigma concentrates on eliminating defects while total QM (TQM), focuses upon improving processes and reducing expenses.

Six Sigma stands for continuous improvement. This method emphasizes eliminating defects using statistical methods such p-charts, control charts, and Pareto analysis.

This method aims to reduce variation in product production. This is done by identifying and correcting the root causes of problems.

Total quality management is the measurement and monitoring of all aspects within an organization. It also includes the training of employees to improve performance.

It is frequently used as an approach to increasing productivity.

What is the difference of a program and project?

A project is temporary; a program is permanent.

Projects usually have a goal and a deadline.

It is often done in a team that reports to another.

A program often has a set goals and objectives.

It is typically done by one person.

What is Six Sigma and how can it help you?

It's an approach to quality improvement that emphasizes customer service and continuous learning. The goal is to eradicate defects through statistical techniques.

Six Sigma was developed at Motorola in 1986 as part of its efforts to improve manufacturing processes.

It was quickly adopted by the industry and many companies are now using six-sigma to improve product design, production, delivery, customer service, and product design.

Why does it sometimes seem so hard to make good business decisions

Complex systems are often complex and have many moving parts. It is difficult for people in charge of businesses to manage multiple priorities simultaneously and also deal with uncertainty.

To make good decisions, you must understand how these factors affect the entire system.

You need to be clear about the roles and responsibilities of each system. Then, you need to think about how these pieces interact with one another.

You need to ask yourself if your previous actions have led you to make unfounded assumptions. If you don't have any, it may be time to revisit them.

For help, ask someone else if you're still stumped after all the above. You may be able to see things from a different perspective than you are and gain insight that can help you find a solution.

How does Six Sigma work?

Six Sigma uses statistical analysis to find problems, measure them, analyze root causes, correct problems, and learn from experience.

The first step is to identify the problem.

The next step is to collect data and analyze it in order to identify trends or patterns.

The problem is then rectified.

Finally, data will be reanalyzed to determine if there is an issue.

This cycle will continue until the problem is solved.

Statistics

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

External Links

How To

How do you do the Kaizen method?

Kaizen means continuous improvement. This Japanese term refers to the Japanese philosophy of continuous improvement that emphasizes incremental improvements and constant improvement. It's where people work together in order to improve their processes constantly.

Kaizen is one method that Lean Manufacturing uses to its greatest advantage. In this concept, employees who are responsible for the production line must identify problems that exist during the manufacturing process and try to solve them before they become big issues. This improves the quality of products, while reducing the cost.

Kaizen is an approach to making every worker aware and alert to what is happening around them. If something is wrong, it should be corrected immediately so that no problem occurs. It is important that employees report any problems they see while on the job to their managers.

Kaizen is based on a few principles. Always start with the end product in mind and work our way back to the beginning. To improve our factory, for example, we need to fix the machines that produce the final product. Then, we fix the machines that produce components and then the ones that produce raw materials. Finally, we repair the workers who are directly involved with these machines.

This is known as "kaizen", because it emphasizes improving each step. When we are done fixing the whole factory, we go back to the beginning and continue until we reach perfection.

You need to know how to measure the effectiveness of kaizen within your business. There are many ways you can determine if kaizen has been implemented well. Another method is to see how many defects are found on the products. Another way is to see how much productivity has increased since implementing kaizen.

To determine if kaizen is effective, you should ask yourself why you chose to implement kaizen. You were trying to save money or obey the law? You really believed it would make you successful?

Congratulations! You are now ready to begin kaizen.